There are rumors of Trump's administration considering whether to convert all OSHA enforcement to state run plans. States have always had this option, and 22 have managed their own enforcement for many years. Safety enforcement in Texas is currently under Federal OSHA. Going to a Texas plan instead should not result in a big change for Texas manufacturers (since all states must enact plans that are at least as protective as Federal OSHA regulations).

I found an article that summarizes some other potential changes in the air...

Of course, all bets are off on predictions these days, but we should keep our eyes open to changes that can affect our businesses and lives.

Who updates your site's OSHA 300 Log of work-related injuries and illnesses?

If you are not the person, please forward a copy of this reminder to them now.

Most companies have production and/or safety leaders completing incident reports and presenting the information to someone in HR, and HR updates and maintains the OSHA 300 log (since they have secure offices). All non-governmental companies that have 10 or more employees are required to maintain a OSHA 300 log each year.

January is the time to check the OSHA log (of work-related injuries & illnesses) for the previous year, then finalize and print a summary of the incidents/illnesses for the year on the OSHA 300A (annual summary form). The OSHA 300A form must be signed by the local President or GM, then posted in the workplace for employees to view. The 300A summary must be posted for all of February through all of March, but most companies keep it posted year-round. Note that companies are not allowed to post the OSHA 300 log itself (privacy issue), so only post the annual 300A summary form.

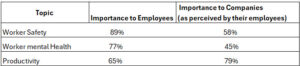

A 2023 survey of 2000 workers reveals worker perceptions of where priorities are on safety, mental health, and productivity.

Ways employees would like for their companies to demonstrate they care about employee safety:

Impact Safety can help with this (contact [email protected])

https://ohsonline.com/articles/2023/03/22/more-than-80-percent-of-employees.aspx?m=1

(The report, The State of Employee Safety in 2023 from Occupational Health & Safety publication)

This article has some good ideas on how we can re-assess our overall facility setup periodically with our safety goggles on.

"By rethinking the layout, it is possible to create a safer working environment for employees, reduce the risk of accidents, and increase productivity."

Topics discussed:

How To Rethink Factory Layout Design to Improve Worker Safety - EHS Daily Advisor

Find out how to improve your factory layout design and provide a safe working environment for everyone in your facility:

https://ehsdailyadvisor.blr.com/2023/03/how-to-rethink-factory-layout-design-to-improve-worker-safety/

#safetyculture #workplacesafety #safetytraining #operations

Production folks are always working on ways to make processes more reliable to prevent physical waste and wasted time. Likewise, we need to put solid effort into increasing the stability of employee safety each year as well. We an do this by assessing potential hazards and identifying ways to control the hazards to mitigate the likelihood of injuries.

This article out of the UK, lists some of the key safety hazards likely exist in most manufacturing companies -that need to be controlled.

Here are five common safety hazards in manufacturing facilities:

https://www.shponline.co.uk/manufacturing/five-common-safety-hazards-in-manufacturing-facilities/

Recap of Key Points: (more…)

Who updates your site's OSHA 300 Log of work-related injuries and illnesses?

I you are not the person, please forward a copy of this reminder to them now.

Most companies have production and/or safety leaders completing incident reports and presenting the information to someone in HR, and HR updates and maintains the OSHA 300 log (since they have secure offices). All non-governmental companies that have 10 or more employees are required to maintain a OSHA 300 log each year.

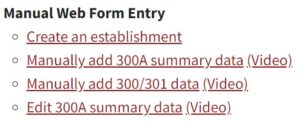

January is the time to check the OSHA log (of work-related injuries & illnesses) for the previous year, then finalize and print a summary of the incidents/illnesses for the year on the OSHA 300A (annual summary form). The OSHA 300A form must be signed by the local President or GM, then posted in the workplace for employees to view. The 300A summary must be posted for all of February through all of March, but most companies keep it posted year-round. Note that companies are not allowed to post the OSHA 300 log itself (privacy issue), so only post the annual 300A summary form.

At the American Society for Safety Professionals annual PDC meeting in DFW this April, one presentation really stood out for me. It was presented by John Goodpaster, CSP, who is the Director of EHS at Briggs Industrial Solutions. The company primarily services material handling equipment. Their business is primarily conducted by solo field workers. They have 1,000 employees who utilize 650 vehicles across 5 states in the South & Southwest. Briggs is an employee-owned company.

Briggs failed in nurturing an effective safety program for years and from 2015-2018 their safety record hit rock bottom, with lots of injuries - and 4 deaths. The company was also losing a stream of clients over their lack of safety performance. John shared a story of how the company was able to turn this situation around and build effective safety processes and an on-going safety culture in the company.

These are some of the steps the company took that led to this major turnaround: (more…)